Liugong excavator accessories mold parts heat treatment requirements and technology

Date of issue:2018-11-23

There are huge differences in the heat treatment process of different materials, how is the heat treatment of the mold parts performed? Today, Liugong Liugong excavator parts manufacturers will answer for you:

Heat treatment requirements of each part of the blanking die:

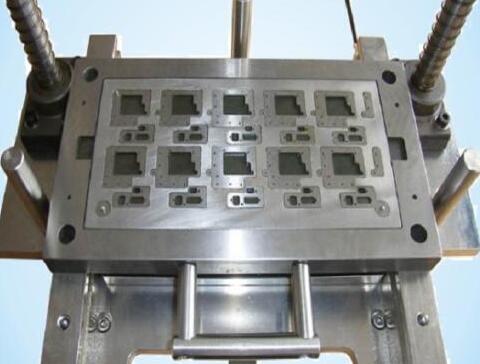

Processing requirements Blanking is one of the basic processes of cold stamping. It is a stamping process in which the stamping die is used to separate the stamped materials on the press. The blanking die is a Liugong excavator accessory die with a cutting edge. During blanking, the cutting edge sinks into the material being punched, and is subjected to fierce impact and fierce friction of the material, so that the cutting edge will be severely worn after a period of use, from sharp at the beginning to blunt at the end. Affect the quality of subsequent products. In order to ensure the long-term stability of the quality of the product parts, this requires the punch of the die to have high wear resistance, and also have a certain compressive strength, bending strength and a certain impact edge. Regarding the concave mold, in addition to the low requirements for bending strength, the requirements for compressive strength and toughness are higher than that of the convex mold. Regarding the above requirements for the punching die convex and concave dies of Liugong excavator accessories, in addition to the correct selection of the steel used for the convex and concave dies, a reasonable heat treatment process is also required to ensure the hardness and toughness requirements after heat treatment. Both are indispensable. .

Sequence organization of heat treatment of forming parts of Liugong excavator parts blanking die

After the final heat treatment is hardened, the process sequence of the heat treatment process organization that needs electric machining is:

Casting → heat treatment annealing → mechanical rough machining → heat treatment quenching and tempering → electric machining (electric spark perforation or wire cutting) processing and forming → clamp repair and assembly.

It can be seen that the heat treatment process of Liugong excavator parts is a very important and indispensable process in die manufacturing. Regarding progressive dies, compound dies and other die with finer azimuth tolerances and dimensional tolerances, not only must abide by the above-mentioned process organization, but in order to reduce heat treatment deformation, heat treatment processes such as stress removal treatment and quenching and tempering are often interspersed in the processing.

For more information about excavator parts, please visit Chuanna Industry (www.acgway.com). I hope this article "Heat Treatment Requirements and Technology of Liugong Excavator Parts Mould Parts" will be helpful to everyone. If you still have something you don’t understand, you can directly leave a message or consult Chuanna Hydraulics National Service Hotline 15850333149, we will solve your doubts as soon as possible!

Company address: no.379, Juji Road, Zhangpu Town, Kunshan City

Company address: no.379, Juji Road, Zhangpu Town, Kunshan City Contact person: Mr. Chen

Contact person: Mr. Chen mobile phone:18888180218

mobile phone:18888180218 Landline:0512-36863852

Landline:0512-36863852