The Kawasaki agent tells you why the diesel engine of the new excavator is overheating?

Date of issue:2018-09-24

The Kawasaki agent tells you why the diesel engine of the new excavator is overheating?

1. Overheating

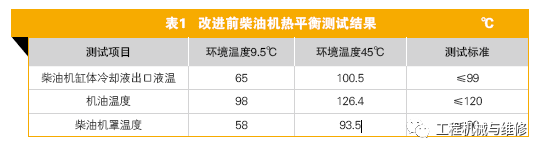

Before the hydraulic excavator leaves the factory, the thermal balance test during diesel engine operation must be carried out. The method is as follows: fully open the diesel engine throttle, and make the excavating boom and stick "hold pressure" overflow to imitate the operating temperature of the diesel engine under full load. Our test results on a certain type of hydraulic excavator prototype show that the diesel engine equipped with this excavator has a high temperature at full load, and its thermal balance test results are shown in Table 1. Excavator accessories Kawasaki agent

It can be seen from the test results that when the ambient temperature is 45°C, the coolant outlet temperature of the diesel engine cylinder block, the temperature of the engine oil and the temperature of the diesel engine room are all high, which clarifies that the excavator is in an environment of 45°C (environmental limit temperature) During operation, the diesel engine will overheat.

2. Analyze the cause of diesel engine overheating

The overheating of the diesel engine of the hydraulic excavator may be caused by the following two reasons: one is that the diesel engine is faulty, resulting in excessive heat generation, and the other is the lack of heat dissipation in the cooling system. When testing the prototype, the diesel engine is in good technical condition, so the cause of overheating should be the lack of heat dissipation. The heat dissipation of diesel engines mainly depends on the radiator, and the heat dissipation ability of the radiator mainly depends on the amount of air passing through the radiator core. Therefore, improving the function of the cooling fan can effectively improve the heat dissipation capability of the radiator.

To improve the function of the cooling fan can go through the following three plans: one is to increase the diameter of the fan, the other is to increase the speed of the fan, and the third is to reduce the gap between the tip of the fan and the wind ring. The diesel electric fan is directly driven by the front belt wheel, and the speed is the same as that of the diesel engine, and the speed of the electric fan cannot be improved. To increase the diameter of the electric fan, a larger radiator must be replaced, and the diesel engine must be re-arranged, which is more difficult to implement. In addition, methods such as increasing the speed of the electric fan and increasing the diameter of the electric fan will increase the power consumption of the diesel engine, so the first and second plans are not advisable. After summarizing and considering, it is more convenient and useful to adjust the size of the wind deflector to reduce the gap between the fan blade tip and the wind circle. Kawasaki Agent

3. Analyze the relationship between blade tip clearance and exhaust air volume

The wind speed on the inlet side of the radiator was measured with an anemometer, and it was found that the wind speed in a single area on the inlet side of the radiator was very small, only about 1m/s, which clarified that the fan has a poor blowing function.

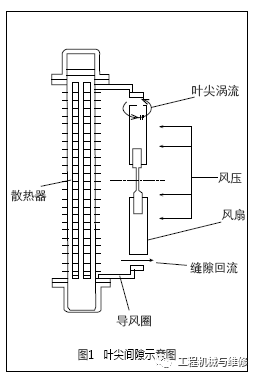

In theory, there are two kinds of air activities in the gap area of the blade tip of the electric fan: one is the pressure difference between the outlet and the inlet of the electric fan, and the airflow driving the outlet of the electric fan flows back to the inlet along the gap between the tip and the wind ring; the other is the blade pressure There is a pressure difference between the wind surface and the suction surface, which drives the airflow to wrap around the gap between the blade tips of the electric fan to form a vortex, as shown in Figure 1. The conflict, impact and vortex loss between the airflow caused by the above two kinds of air activities can directly lead to the reduction of the exhaust air volume of the electric fan and the operation efficiency. Therefore, the diameter of the air guide ring is appropriately reduced, the blade tip gap of the electric fan is reduced, the gap backflow and the blade tip vortex can be reduced, and the exhaust air volume and operation efficiency of the electric fan are effectively improved.

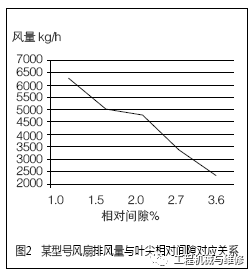

An experimental organization once used an electric fan with a wind pressure of 400 Pa to blow the radiator, and measured the correspondence between the fan's exhaust air volume and the relative blade tip clearance (the ratio of the blade tip clearance to the fan diameter) as shown in Figure 2. It can be seen from the curve in Figure 2 that when the relative gap increases from 1% to 1.5%, the fan exhaust volume decreases faster; when the relative gap increases from 1.5% to 2%, the fan exhaust volume decreases. Steep, when the relative gap increases from 2% to 3.6%, the fan exhaust air volume drops sharply, and the air volume decline trend is more significant.

The diameter of the diesel electric fan of the excavator is φ550 mm, the inner diameter of the wind deflector ring is φ590mm, and the average blade tip clearance is 20mm. It is calculated that the relative clearance of the electric fan is 3.6%. It can be judged by referring to the curve in Figure 2 that if the relative gap is slightly reduced from the current 3.6%, the fan exhaust will increase significantly.

4. Improvement methods

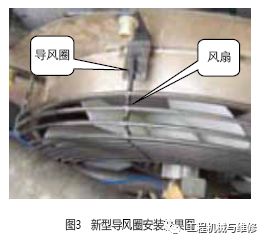

It was decided to change the inner diameter of the air guide ring of the diesel engine radiator hood from φ590mm to φ580mm (the blade tip clearance is 15mm). The function diagram of the new air guide ring device is shown in Figure 3. After the improvement, the relative clearance of the blade tip of the electric fan is 2.7%. As can be seen from Figure 2, the air volume of the electric fan will be greatly improved. Kawasaki Agent

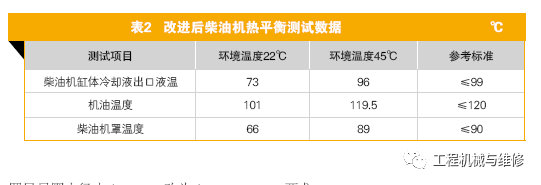

In order to verify the effect of improvement, the diesel engine was tested for thermal balance again. The test data is shown in Table 2.

It can be seen from Table 2 that after the blade tip clearance and the relative clearance are changed, the temperature of the diesel engine water outlet, the oil temperature and the temperature of the diesel engine cover at an ambient temperature of 45°C will drop by 5.5°C, 6.9°C and 4.5°C, and all of them have reached the test specification requirements.

The relationship between the tip clearance and the heat balance temperature of the whole machine is more complicated. In practical applications, the improvement of the heat balance of the whole machine is also closely related to many factors such as the structure of the air duct, the viewpoint of the electric fan, the number of electric fan blades, the projected area of the electric fan, and the shape of the electric fan. Only after the blade tip clearance changes, the effect on the heat balance becomes more obvious. Kawasaki Agent

Company address: no.379, Juji Road, Zhangpu Town, Kunshan City

Company address: no.379, Juji Road, Zhangpu Town, Kunshan City Contact person: Mr. Chen

Contact person: Mr. Chen mobile phone:18888180218

mobile phone:18888180218 Landline:0512-36863852

Landline:0512-36863852